About company

«STEELTECH» - the strength of the future!

«STEELTECH» manufactures products made from wear‐resistant steels for companies that face daily challenges posed by abrasive and impact wear on their equipment. These include enterprises in road construction, mining, processing, machine-building, and other manufacturing industries.

«STEELTECH» — is a leading manufacturer in Kyrgyzstan of products and components made from wear-resistant HARDOX®steel, produced by the Swedish company SSAB. With substantial stockpiles of HARDOX® steel and prompt replenishment, the company efficiently meets the needs of its partners.

STEELTECH's mission is to provide industrial enterprises with high-quality, wear-resistant products made from HARDOX steel, thereby enhancing the reliability and efficiency of their equipment. We are committed to long-term partnerships by promptly responding to our clients needs and offering solutions capable of withstanding extreme operating conditions.

High hardness and impact toughness where it matters.

Hard, durable, and reliable—with guaranteed properties, versatile in use and exceptionally formable—there are many ways to describe Hardox® steel, and in every instance you receive a material of exceptional quality.

Maximum performance from steel thanks to technical support.

Are you considering modernisation but still have many questions? Our technical support specialists will help optimise your choice of materials and refine your design, so you can fully capitalise on the benefits of our materials.

Outstanding sustainability performance – now and in the future.

Less steel, less weight, less maintenance, less fuel: minimal environmental impact with maximum performance.

Our advantages

Official partner SSAB

High speed of order processing

Own steel warehouse Hardox

Streamlined logistics

All types of metal cutting

Many satisfied customers

Own engineering and design service

Own production

Flexible pricing policy

Advice on the application of all steels

Our products

HARDOX® steel is a trademark of high-strength wear-resistant steel produced by the Swedish company SSAB (Swedish Steel AB). This steel is known for its high strength, wear resistance, and resistance to mechanical damage, making it popular in various industries.

High hardness: The hardness of HARDOX® steel varies depending on its grade (e.g., Hardox 400, Hardox 450, Hardox 500, etc.), where the numbers indicate the hardness level on the Brinell scale (HB).

Impact toughness: Despite its hardness, the steel retains high toughness, preventing cracking under impact loads.

Abrasion resistance: Used in conditions requiring a long service life in environments with intensive friction or impact loads.

Unlike many other hard steels, HARDOX® combines strength with ductility. This means the material is not prone to cracking under stress, impacts, or vibrations.

Used in tipper truck bodies, road rollers, graders, drilling rigs, and crushing equipment. HARDOX® increases the lifespan of these components, reducing replacement costs.

Equipment longevity: due to reduced wear.

Weight reduction: of structures, as thinner metal can provide the same strength.

Combination of Hardness and Impact Toughness in HARDOX®

It is precisely hardness that gives HARDOX® steel its unique wear resistance and structural strength. Hardness minimises wear by preventing sharp particles of abrasive materials from cutting into the material. HARDOX® steel retains its original wear resistance throughout its entire service life, as its hardness remains unchanged. Hardness also implies high yield strength and tensile strength values, which allow the structure to maintain its shape without deformation.

Another advantage of HARDOX® is its impact toughness. While hardness provides wear resistance and strength, impact toughness allows HARDOX® steel to be bent, formed, and welded without cracking. If a HARDOX® steel sheet experiences stress beyond its yield strength and undergoes plastic deformation—whether intentionally during manufacturing or due to the impact of a heavy rock at a worksite—cracking will not occur. Even if a localised crack forms, it will not propagate to other areas.

The impact toughness values for Hardox HiTuf, Hardox 450, and Hardox 500 are guaranteed minimums at -40°C, -20°C, and 0°C, respectively. Compared to standard S355 steel, Hardox HiTuf, for example, has three times greater resistance to permanent deformation (hardness) while maintaining the same resistance to cracking (impact toughness).

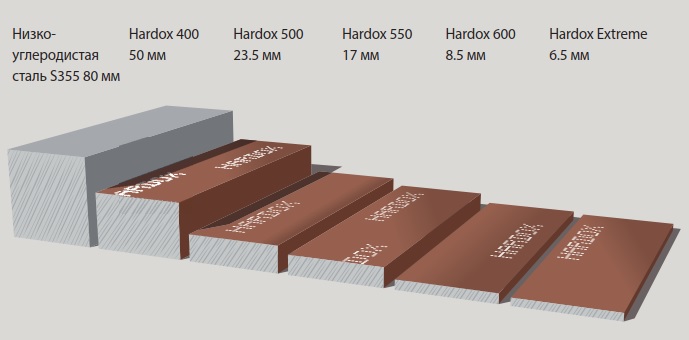

Fighting Wear and Weight

What steel hardness suits you? Most likely, a combination of steel grades that withstand different wear conditions. In a tipper truck body, one type of HARDOX® steel may be used for the floor, while another is used for the sides, ensuring an equal service life for the entire body. According to calculations using the WearCalc 2.0 program (see illustration), Hardox 600 will last nine times longer than low-carbon steel under identical wear conditions.

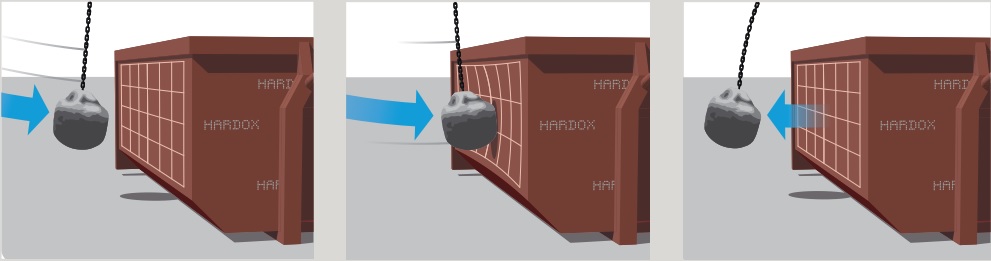

A Brief Visual Example of Hardox® Strength

It takes just a fraction of a second to witness the unique performance characteristics of HARDOX® steel. The impact force from large and heavy objects is distributed across the entire surface, preventing dents and cracks. The metal absorbs energy and returns to its original shape, similar to how a tennis racket strikes a ball.

Whatever your tasks may be,

we can solve them together.

Whatever the challenge, we want the advantages of our wear-resistant steel

to be utilised to the

fullest. Our experts collaborate with renowned brands

and are ready to assist you as well. Let’s get

started!

More details

Increase your payload by using thinner Hardox® sheet steel. By choosing 5 mm Hardox® steel instead of 6 mm material, you can reduce weight and boost payload capacity by 17%.

Extend the lifespan of your equipment

Replace mild steel with Hardox® wear-resistant sheet steel to significantly extend your equipments service life.Or reduce weight while maintaining durability by using thinner Hardox® wear-resistant steel.

Cost savings

Minimise maintenance costs and downtime with Hardox® wear-resistant steel. Hardox® steel makes equipment more predictable, allowing for better maintenance planning.

Steel for all wear conditions

A wide range of Hardox® steel grades is available to meet various wear resistance requirements. From mining equipment to construction machinery and heavy-duty transport, our experts will help you select the right material for your needs. At the same time, this steel has a minimal environmental impact. Don’t compromise on the service life and performance of your equipment – choose Hardox® wear-resistant steel.

Hardox® 500 Tuf – wear-resistant structural steel for heavy-duty applications

Hardox® 500 Tuf is a next-generation wear-resistant steel sheet, offering exceptional hardness, strength, and impact toughness. Its high quality is guaranteed.

Steel Hardox® HiAce resistant to corrosive wear

Hardox® HiAce is a corrosion-resistant steel designed for acidic environments. How about tripling the service life?

Hardox® 600 – extremely hard wear-resistant steel

Designed for high-performance wear components operating in harsh conditions, where service life and equipment efficiency are critical.

Hardox® wear plate steel is a material capable of increasing productivity.

Hardox® 500 Tuf steel for increased productivity in mining processes

Can your valuable mining equipment withstand daily impacts while achieving high performance levels and ensuring necessary profitability? At Schlam, we know this is possible by increasing payload capacity by 20%. Hardox® 500 Tuf steel helps protect investments in the bodies of haul trucks. Its guaranteed hardness ranges from 475 to 505 Brinell, with an impact work of 27 J at -20°C and a standard value of 50 J at -40°C, making it the ideal material for use in low-temperature conditions.

Hardox® 500 Tuf – ideal steel for the processing industry

Containers made from Hardox® 500 Tuf steel are lightweight, highly durable, and ready for operation in the most challenging conditions of the recycling industry. The Finnish company Ferreus switched to using Hardox® 500 Tuf steel and reduced the weight of their containers by over one ton. Heavy and sharp materials, such as scrap metal, reinforced concrete, and demolished building components, pose no challenge to Hardox® 500 Tuf steel. A recycling container will remain in excellent condition after an entire day of transporting heavy loads.

Hardox® 500 Tuf steel increases the reliability of concrete mixers

By using Hardox® 500 Tuf steel, concrete mixers become lighter and more durable. Engineers at the German company Stetter know this firsthand, as they were able to reduce the weight of their drums. Using wear-resistant Hardox® 500 Tuf steel instead of Hardox® 400 and Hardox® 450 allows for thinner drum walls, thus reducing weight while maintaining long service life. When using material of the same thickness, the drum can last even longer. In any case, Hardox® 500 Tuf wear-resistant steel enhances the competitiveness of this product.

Hardox steel grades

Our projects

Questions We have answers!

How to Buy Hardox® Steel in Kyrgyzstan?

Explore the information on our website, select the required items, and submit your order online. You can also contact us by phone: +996 558 90 77 07 for consultation. Check stock availability — out-of-stock items are delivered within 15–20 days. Products are supplied exclusively to end customers without intermediaries. We guarantee quality and reliable deliveries. Call us or submit your request now!

Our clients