The Use of Hardox® Steel in Road Construction

Hardox® steel is an innovative solution for applications where strength, wear resistance, and durability are paramount. In the road construction industry, where machinery and structures face extreme loads, abrasive wear, and harsh operating conditions, Hardox® proves to be an indispensable material that ensures uninterrupted operation and cost reduction.

Where is Hardox® Used?

- Tippers and Special Equipment: truck bodies, floors, and sides exposed to impact loads and abrasion from gravel, sand, and soil.

- Road Machinery: excavator buckets, bulldozer blades, grader and paver blades operating under high mechanical stress.

- Road Infrastructure: slope reinforcement elements, safety barriers, crushing plants, and road surface repair components.

- Bridge Construction: wear-resistant pads, support structures, and elements resistant to vibrations and corrosion.

Benefits of Hardox® in Road Construction

- Exceptional Wear Resistance: lasts 2–4 times longer than regular steel, reducing the frequency of part replacement.

- Strength and Lightness: enables the creation of thinner, lighter structures without compromising reliability, improving fuel efficiency.

- Resistance to Corrosion and Temperature Extremes: maintains properties in humidity, frost, or heat — essential for any climate.

- Resource Savings: reduces repair, downtime, and disposal costs, supporting eco-friendly projects.

Why Choose Hardox®?

Using Hardox® steel is an investment in uninterrupted construction and long-term savings. It combines cutting-edge metallurgical technology with the demands of the modern road sector, where every part must perform at its peak. Choosing Hardox® means choosing reliability, cost reduction, and enhanced project efficiency.

Trust Hardox® — the steel that builds the roads of the future today.

The Use of Hardox® Steel in the Mining Industry

The mining industry requires materials that can withstand extreme conditions: impact loads, abrasive wear, vibration, and harsh environments. Hardox® steel is ideal for such challenges, ensuring equipment reliability even under the toughest operating conditions. It's the choice of companies that value durability, resource efficiency, and uninterrupted operations.

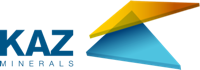

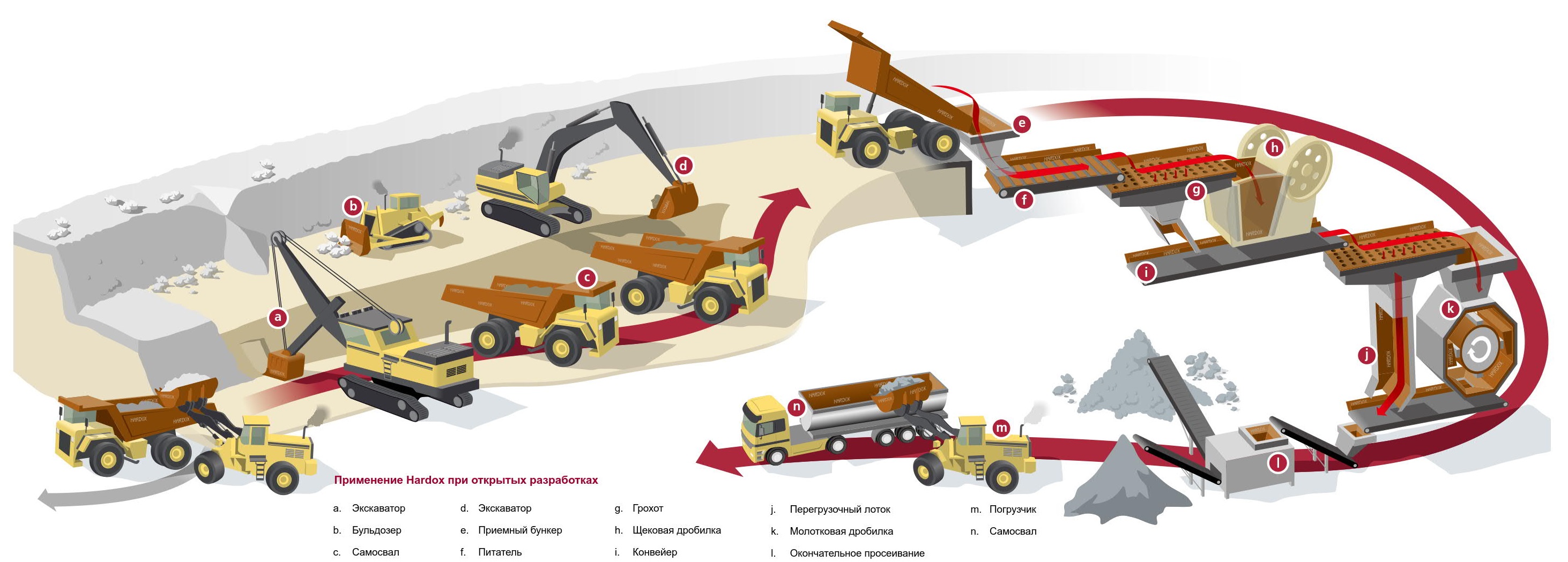

Where is Hardox® Used?

- Tippers and Mining Equipment: truck bodies, floors, and sides, as well as excavator and loader buckets exposed to ore, stones, and abrasive rocks.

- Crushing and Screening Equipment: hammers, blades, crusher linings, mills, and screens processing hard rock materials.

- Conveyor Systems: belts, rollers, and chutes resistant to wear during raw material transportation.

- Bunkers and Storage Units: reinforced walls for storing ore, coal, or crushed stone.

- Drilling Equipment: wear-resistant components of drill rods, protective casings, and fastening elements.

- Mine Equipment: structures exposed to constant mechanical stress and corrosion in high humidity conditions.

Benefits of Hardox® in Mining

- Maximum Wear Resistance: lasts 4–6 times longer than regular steel, extending part life and cutting replacement costs.

- Impact Resistance: maintains integrity under dynamic loads and vibration from crushing and transportation processes.

- Adapted to Extreme Conditions: resists corrosion, temperature swings, and abrasion in deep mines or open pits.

- Weight Optimisation: allows for thinner sheets without losing strength, reducing machine weight and fuel use.

- Reduced Downtime: minimal maintenance and repair, increasing efficiency and profitability of operations.

Why Choose Hardox®?

In mining, every minute of downtime is costly. Hardox® is more than just steel — it’s a technology that reduces expenses and boosts productivity. It allows you to:

- Extend service intervals of equipment.

- Reduce waste thanks to longer-lasting components.

- Operate in any climate — from arctic cold to tropical humidity.

By choosing Hardox®, you’re investing in reliability that pays off over the years. This is steel that withstands depth, height, and pressure — turning mining challenges into steady results.

Trust Hardox® — the material that mines success with you!

The Use of Hardox® Steel in the Recycling Industry

In the recycling industry, where equipment faces extreme loads, abrasive wear, and aggressive environments daily, Hardox® steel plays a crucial role in ensuring smooth operations and maximum efficiency. Its unique properties enable solutions for the most demanding tasks — from crushing hard materials to handling chemically active substances.

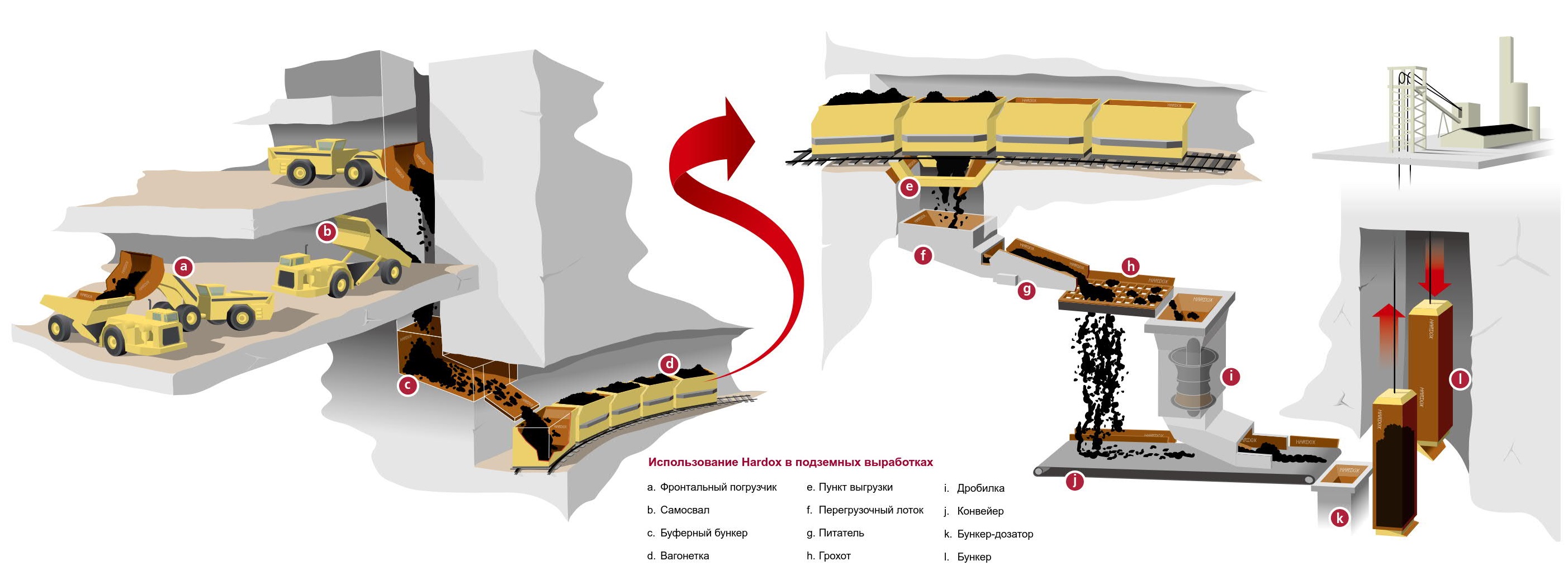

Where is Hardox® Used?

- Crushing and Screening Equipment: knives, hammers, screens, and wear parts for crushers, shredders, and screens handling metal, glass, plastic, and construction waste.

- Conveyor Systems: trays, chutes, and rollers resistant to friction and impact during material transport.

- Bunkers and Storage Units: reinforced walls and bottoms for storing abrasive or chemically aggressive materials.

- Waste Processing Equipment: shredders, presses, and waste sorting line components working under high mechanical and corrosive stress.

- Chemical and Metallurgical Industry: components in contact with acids, alkalis, or high-temperature environments.

Benefits of Hardox® in Recycling

- Outstanding Wear Resistance: lasts 3–5 times longer than conventional steel, reducing replacement frequency.

- Corrosion Resistance: special Hardox® grades (e.g. Hardox® HiTuf) withstand moisture, chemicals, and temperature changes.

- Strength and Lightweight Design: allows for reduced metal thickness without compromising reliability, cutting equipment weight and energy consumption.

- Minimal Downtime: fewer repairs and maintenance, increasing operational profitability.

- Environmental Responsibility: longer part life reduces waste and supports sustainable practices.

Why Choose Hardox®?

Hardox® steel is not just a material — it’s a strategic solution for the recycling sector, where every minute of downtime means financial loss. It optimises production, reduces operating costs, and boosts your business’s competitiveness. Combining advanced metallurgical technology with proven reliability, Hardox® becomes the foundation for equipment that works longer, more efficiently, and more safely.

Choose Hardox® — the steel that turns recycling challenges into growth and innovation opportunities.

How to Buy Hardox® Steel in Kyrgyzstan?

Browse the information on the website, select the desired items, and place your order online. You can also contact us at Phone: +996 558 90 77 07 for consultation. Check stock availability — out-of-stock items are delivered within 15–20 days. Products are sold only to end customers, with no intermediaries. We guarantee quality and reliable delivery. Call or send your request now!

Our Clients